GH 4 wheel grain wagons

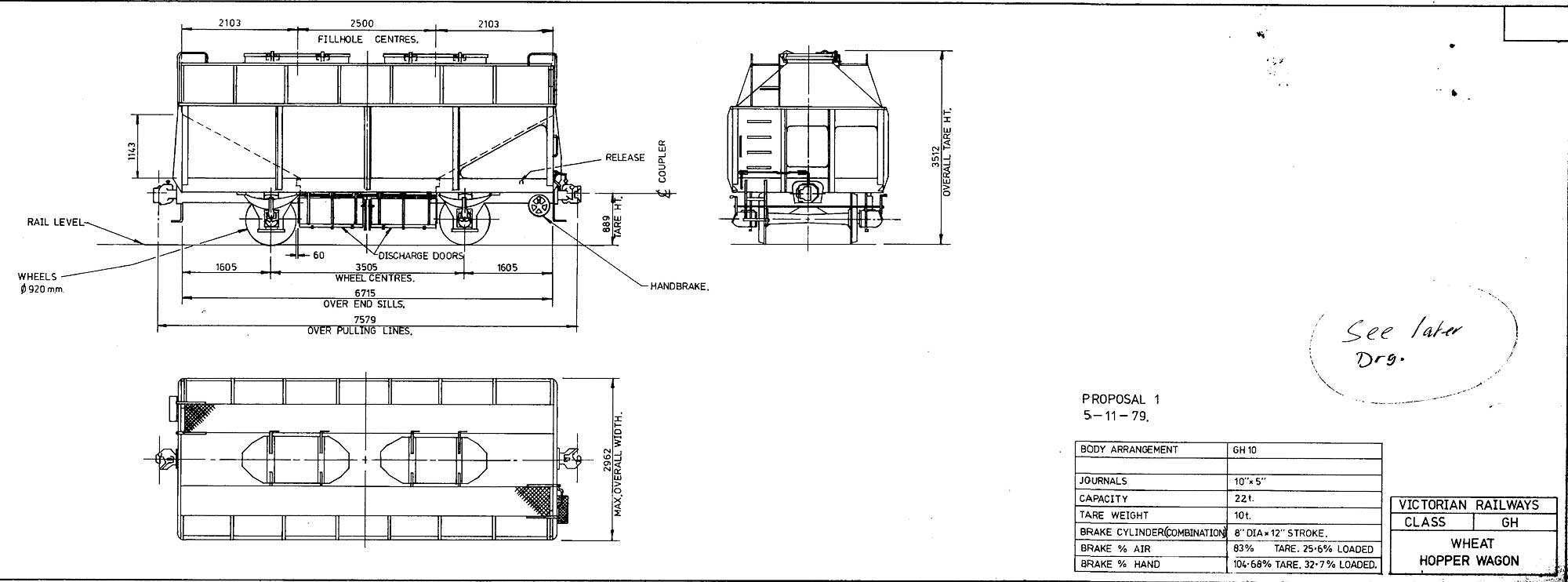

From 1979 until 1982, 810 GYs were converted to GHs. The original design had four discharge chutes but this arrangement discharged wheat too fast for the unloading equipment to handle so was modified to two chutes to lower the rate. It is not known if any four chute GHs were converted to two chute.

Early GHs had two roof hatches. Later versions, and the vast majority, had one long roof hatch, and all were fitted with wheel handbrakes during the conversion.

After the initial modification there were problems accessing the brake equipment. It was proposed to move it to a cutaway section as shown on GH 243 (further down the page), but the expense of carrying out this and the change to two discharge chutes saw it abandoned, thus the cut-out sections remained devoid of brake equipment.

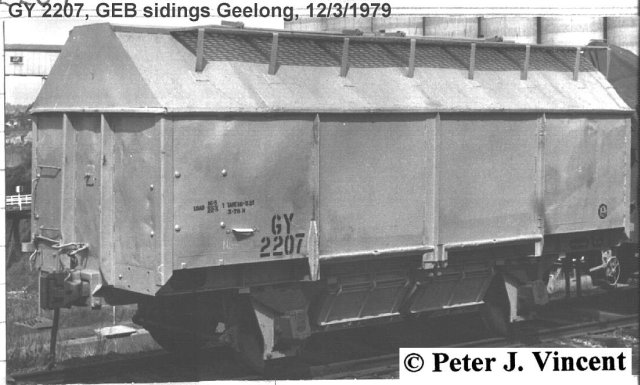

According to correspondence between the VR and the GEB (Grain Elevators Board), it appears that the impetus to convert GYs into rapid discharge vehicles was not because it was cheaper than building new GJF/X wagons but rather their ability to still run on lightly laid lines where GJX/Fs could not. The GEB contributed funds to build the first 400 GHs as a result of the test of GY 2207. Interestingly the GEB wanted to choose the wagon colour and affix their logo to them to which VR responded with a polite "NO".

Trains of GHs were notoriously deficient in braking power. This was because GHs had their tare weight increased by the conversion and could be, and were, loaded with more wheat than a GY, but the braking system was not improved to compensate. Many a driver’s blood pressure was seriously raised bringing solid blocks of GHs down long steep grades such as those on the Bendigo line and from Warrenheip to Geelong.

ABOVE: GH 1 shortly after being re-coded from GY 2207 BELOW: GH 2 and GH 1 (the prototypes) at Newport, notice the two different styles of walkway supports, also note that the internal lashing ring"bubbles" have been removed, later conversions did not bother with this cosmetic enhancement. both photos March 1979

ABOVE: GH 9 and BELOW: GH 18 at Ballarat workshops, prior to entry into service, 1978. (both photos courtesy Peter J Vincent)

ABOVE & BELOW: Very early conversions retained their external lashing rings.

ABOVE & BELOW: GH 210 at Williamstown, late 1979. I'm curious as to why this just built at Ballarat GH would end up at Williamstown as there were no bulk grain facilities there.

ABOVE: As a test GH's 155 and 336 were fitted with European style axleboxes in 1980 and tested at high speed. photo at Glenorchy March 1982.

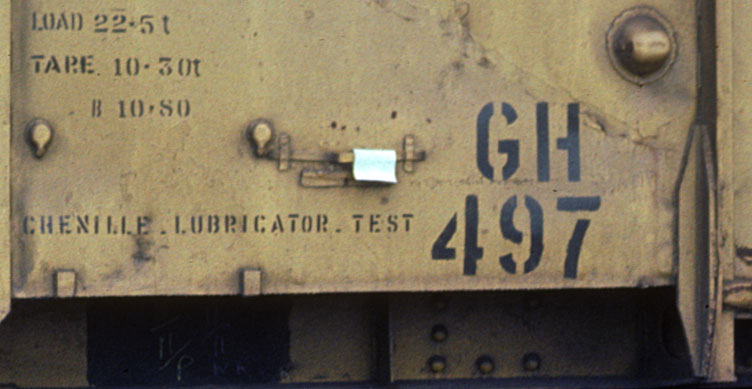

ABOVE & BELOW: GH 497 at Tottenham, March 1983, photos courtesy Rob O'Regan

ABOVE & BELOW: Towards the end of the GY to GH conversion program GH 800 was fitted with this fibreglass top, presumably to reduce tare weight. It is not known if any other GH's were thus fitted. Photographed at Bendigo workshops, Nov. 1982 (above) and at Sunshine Jan 1983 (below) Both photos courtesy Rob O'Regan

ABOVE: GH 806 at Bendigo North, Nov. 1982, photo courtesy Rob O'Regan

ABOVE: GY 893 under conversion to a GH, the doors have been removed and a hole cut in the floor for the discharge chutes. 1978. Ballarat workshops, courtesy Peter J Vincent.

ABOVE: Unknown GH after rebuilding but before painting at Ballarat workshops, late 1979.

ABOVE: A rake of GHs during conversion at Ballarat workshops, 1979.

ABOVE: GY 2207 was issued to traffic to evaluate the design, it returned to the workshops for modifications and returned as GH 1. photo courtesy Peter J Vincent

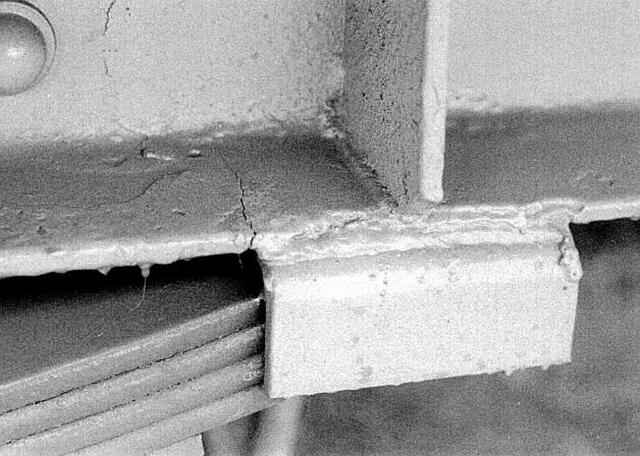

ABOVE: Soon after being built the GH's started to suffer serious frame cracking. The cover allowed much more wheat to be loaded into them than a GY with a tarpaulin.

ABOVE: Diagram for the original design with four discharge chutes and two loading hatches. BELOW: The later design with 2 discharge chutes.